Increase Uptime and Improve Performance Whilst Lowering Costs.

As a renowned Manchester Engineering Company, CPM Engineering have over 25 years of experience in Electrical and Mechanical Maintenance Services and 24/7 Solutions.

Our Engineering and Repairs Workshop, based in Manchester, is one of the largest in the UK and represents a three million pound investment. It hosts our 15 tonne lifting facility and is manned by our Specialist Engineers to provide 24/7 Maintenance Solutions and Electrical and Mechanical Services.

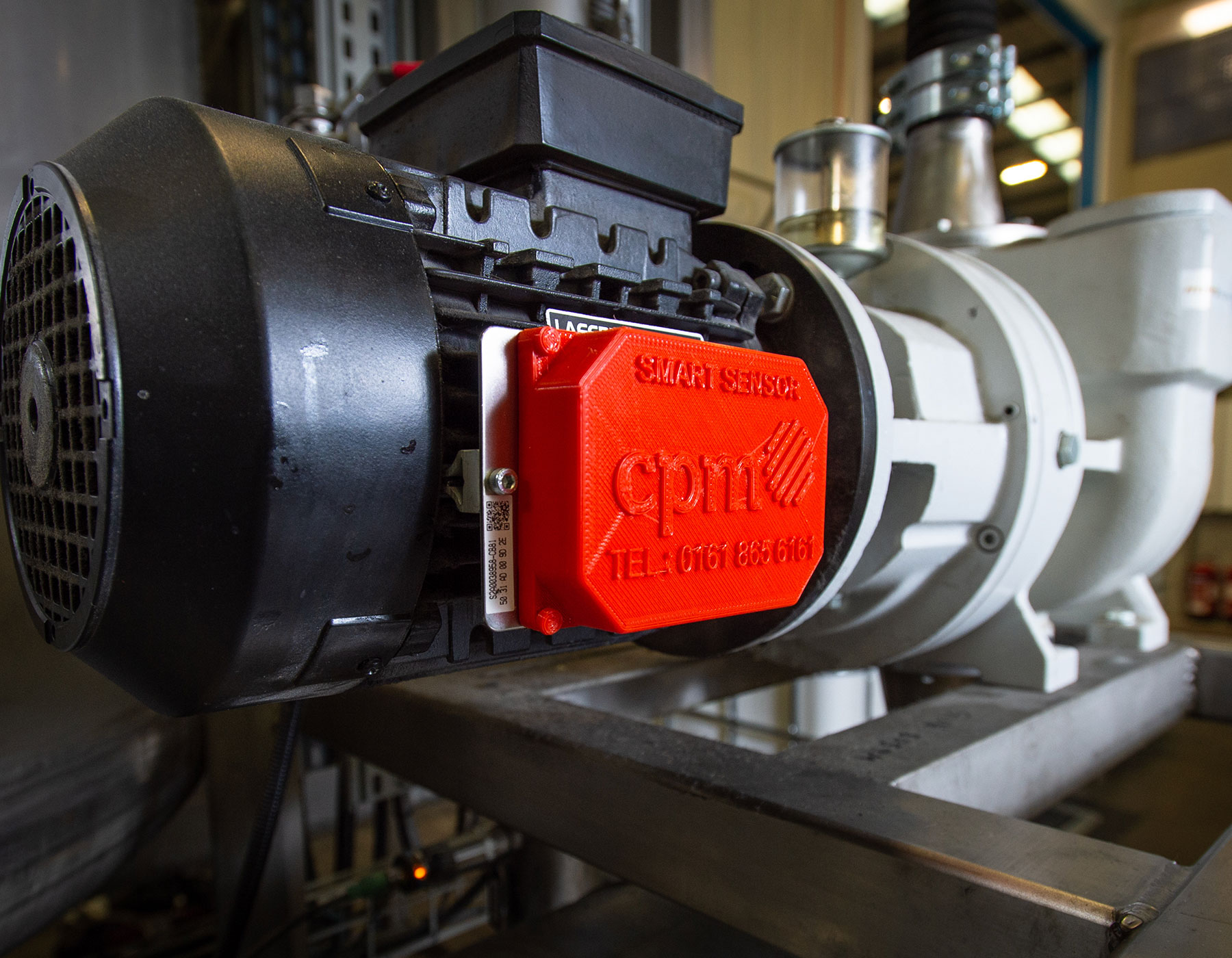

We believe that it is better to prevent a problem than to fix it, which is why we don’t just offer ad-hoc repairs, we offer solutions.

We are experts in Condition Based Monitoring techniques and Root Cause Failure Analysis, deploying Resource Management technology such as Vibration Analysis, Ultrasound, Oil Analysis, Thermography and Laser Alignment.