Ensuring Reliability: The Vital Role of Testing Rotating Machines After Repair

Rotating machines, such as pumps, gearboxes, electric motors and drive systems are the workhorses of many industrial and commercial applications, facilitating critical processes and operations.

When these machines fail, the consequences can be costly in terms of both downtime and repair expenses. That’s why, in the realm of equipment maintenance and repair, it’s not just about fixing what’s broken; it’s about understanding why it broke and ensuring it won’t happen again.

Testing rotating machines after repair is a crucial step in achieving this objective and driving reliability in industrial operations.

Understanding the Root Cause of Failure

Before we delve into the importance of post-repair testing, let’s emphasise the significance of comprehending the root cause of the failure. When a rotating machine breaks down, it’s essential not to treat the symptoms alone but to diagnose the underlying issue. Was it a mechanical failure due to wear and tear, a lubrication problem, an electrical fault, or something else entirely? Identifying the root cause is like solving a puzzle, and without this understanding, any repair is incomplete.

The Repair Specification

Understanding the root cause of failure is the cornerstone of executing an effective repair specification. It guides engineers and technicians in addressing the specific issues that led to the breakdown, ensuring that the repair process is not just a temporary fix but a lasting solution. Without this knowledge, the repair specification risks being a mere shot in the dark, leaving room for the same problem to recur.

The Role of Testing

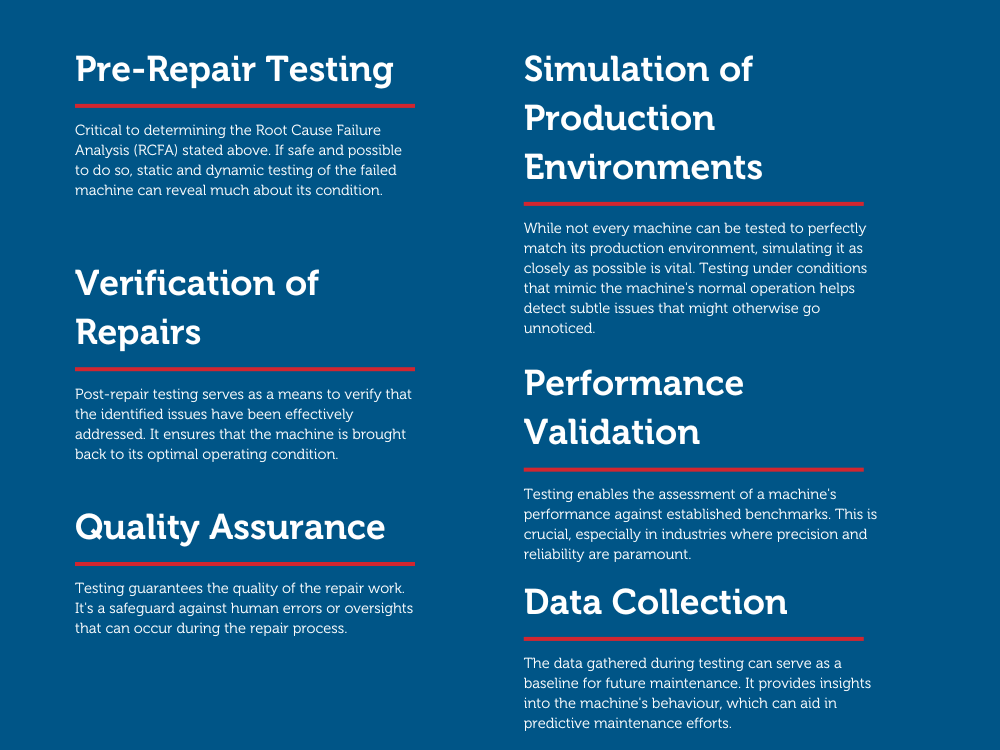

But the role of testing is indispensable in the repair and maintenance of rotating machines. Here’s why:

- Pre-repair testing is critical to determining the Root Cause Failure Analysis (RCFA) stated above. If safe and possible to do so, static and dynamic testing of the failed machine can reveal much about its condition.

- Verification of repairs: Post-repair testing serves as a means to verify that the identified issues have been effectively addressed. It ensures that the machine is brought back to its optimal operating condition.

- Quality assurance: Testing guarantees the quality of the repair work. It’s a safeguard against human errors or oversights that can occur during the repair process.

- Simulation of production environment: While not every machine can be tested to perfectly match its production environment, simulating it as closely as possible is vital. Testing under conditions that mimic the machine’s normal operation helps detect subtle issues that might otherwise go unnoticed.

- Performance validation: Testing enables the assessment of a machine’s performance against established benchmarks. This is crucial, especially in industries where precision and reliability are paramount.

- Data collection for future maintenance: The data gathered during testing can serve as a baseline for future maintenance. It provides insights into the machine’s behaviour, which can aid in predictive maintenance efforts.

Driving Reliability through Testing

In industrial settings, reliability is the holy grail. Downtime is expensive, and unexpected breakdowns can have cascading effects on operations. By testing rotating machines after repair, industries can significantly enhance their reliability. They can be confident that the root causes of previous failures have been addressed, and the machine is fit to perform its duties under operational conditions.

While it may involve some investment in terms of time and resources, this approach pays off. It reduces the risk of costly breakdowns, extends the lifespan of equipment, and ultimately contributes to smoother and more efficient industrial operations.

In conclusion, testing rotating machines after repair is not just a formality; it’s a strategic imperative. It ensures that repairs are effective, addresses the root causes of failure, and contributes to the overall reliability of industrial equipment. In an era where downtime is expensive and operational efficiency is paramount, investing in post-repair testing is an investment in the future success of any industrial operation.

Learn more about our maintenance support and rotating machinery management services.