The Significance of Reliability in Repairing Rotating Machines

Rotating machines, such as motors, gearboxes, pumps, and fans, are vital components in various industrial sectors, including manufacturing, power generation, transportation and even data centres and shopping centres. These machines play a crucial role in maintaining productivity, safety and overall operational efficiency.

However, the reliability of rotating machines can significantly impact the cost of the processes. Unplanned breakdowns and downtime can lead to costly repairs, loss of production, and potential safety hazards. Therefore, achieving high reliability in repairing rotating machines is of utmost importance.

Importance of Reliability in Rotating Machines

Reliability refers to the ability of a machine to perform its intended function under specific conditions for a given period without failure. In the context of rotating machines, high reliability ensures consistent performance, minimises unplanned downtime, and maximises the Mean Time Between Failures (MTBF). Many of CPM’s customers make MTBF a critical metric used to measure the reliability of a machine and represents the average time between consecutive failures.

Several reasons highlight the importance of reliability in repairing rotating machines:

- Minimising Downtime: Downtime due to unexpected failures can lead to production or operational delays, loss of revenue, and increased maintenance costs. High reliability ensures that rotating machines function as intended for extended periods, reducing the frequency of unscheduled maintenance and downtime.

- Improving Safety: In industries where rotating machines operate under high loads and speeds, unexpected failures can also pose significant safety risks. A reliable machine is less likely to experience sudden malfunctions that may result in accidents or injuries to operators.

- Optimising Maintenance Costs: We all recognise that regular preventive maintenance is necessary to keep rotating machines in top condition. However, unnecessary maintenance can be costly and can disrupt operations. By maximising MTBF, maintenance activities can be better planned and executed, leading to reduced maintenance costs.

- Enhancing Productivity: Reliable rotating machines support smooth and uninterrupted operations, contributing to increased productivity and efficiency. Organizations can meet production targets and customer demands more consistently with minimal interruptions.

- Extended Service Life: A reliable machine is less likely to experience premature wear and tear. This extended service life leads to reduced capital expenditures on replacements and an overall better return on investment.

- Sustainability and Environmental Impact: Machines with higher reliability often lead to reduced energy consumption and emissions. Alignment, CBM, lubrication and smart sensors can also contribute to increasing the life of machines leading to lower environmental impact over their lifecycle.

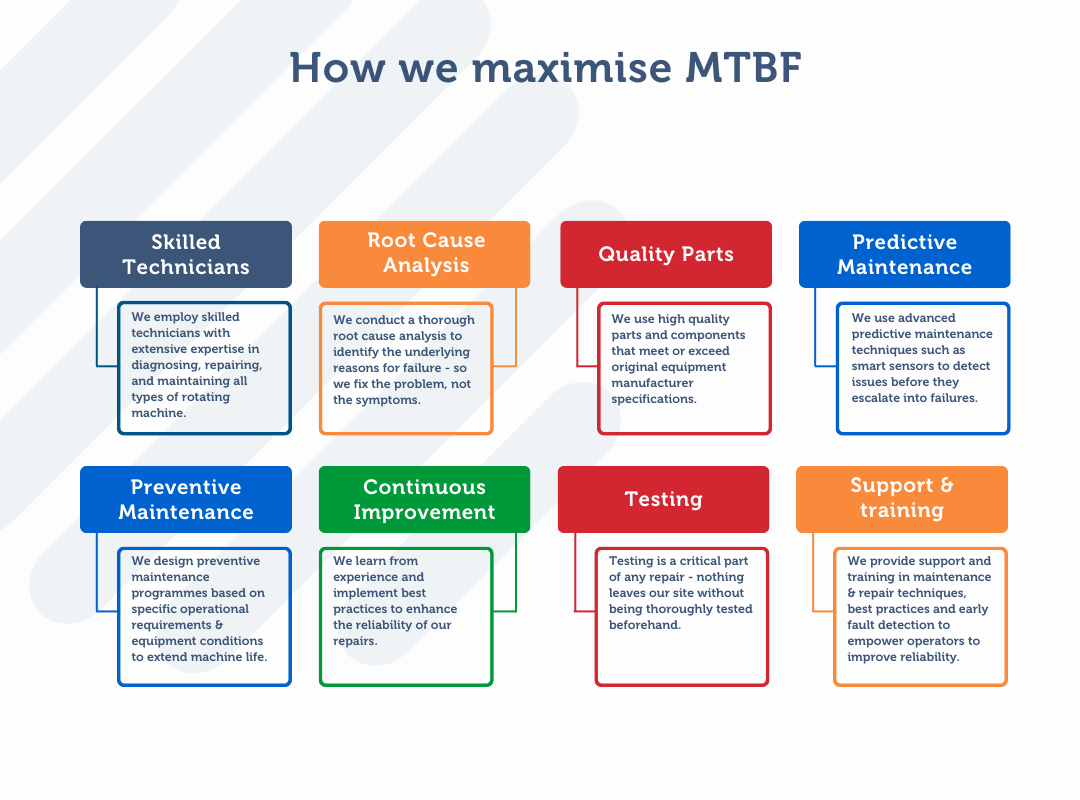

Our Approach to Maximise MTBF

CPM Engineering is a leading provider of rotating machine repair and maintenance services, known for its commitment to ensuring high reliability and maximising MTBF. The company employs a comprehensive set of strategies and practices to achieve this goal:

CPM Engineering is a leading provider of rotating machine repair and maintenance services, known for its commitment to ensuring high reliability and maximising MTBF. The company employs a comprehensive set of strategies and practices to achieve this goal:

- Skilled Technicians: CPM Engineering employs skilled technicians with extensive expertise in diagnosing, repairing, and maintaining various types of rotating machines. The team’s experience and knowledge and adherence to sound procedures developed within its ISO 9001 registration play a crucial role in ensuring reliable repairs and ongoing maintenance.

- Root Cause Analysis: If you don’t know why a machine has failed the corrective actions could be floored. CPM Engineering conducts a thorough root cause analysis to identify the underlying reasons. This analysis helps to address the root issues rather than just the symptoms, reducing the likelihood of recurrent failures.

- Quality Parts and Components: During repairs, CPM Engineering uses high-quality parts and components that meet or exceed original equipment manufacturer (OEM) specifications. This practice ensures that repaired machines perform optimally and reliably.

- Predictive Maintenance: CPM Engineering utilises advanced predictive maintenance techniques, such as smart sensors, vibration analysis, thermal imaging, and oil analysis, to detect potential issues before they escalate into failures. By identifying early warning signs, corrective actions can be taken proactively, maximising MTBF.

- Preventive Maintenance Programmes: The company designs tailored preventive maintenance programmes for its customers based on specific operational requirements and equipment conditions. These programmes aim to proactively maintain the health of rotating machines and extend their service life.

- Continuous Improvement: CPM Engineering emphasises a culture of continuous improvement. They regularly assess repair and maintenance processes and update equipment. They also learn from past experiences, and implement best practices to enhance the reliability of their services. Case studies are also used to compare with other sectors.

- Testing: Without testing machines following repair how can CPM’s customers have confidence that it will operate successfully when returned to production. Testing is a critical part of any repair organisation’s facility to ensure it operates within the OEM’s specification.

- Customer Support and Training: CPM Engineering provides comprehensive training. They educate their team and also customers in maintenance and repair techniques, best practices, and early fault detection, empowering the operators to contribute to the reliability of their rotating machines.

Conclusion

In conclusion, the importance of reliability in repairing rotating machines cannot be overstated. It directly impacts productivity, safety, maintenance costs, and the overall success of the process. By maximising MTBF, organisations can reduce unplanned downtime, increase productivity, and achieve better returns on investment. CPM Engineering’s approach to ensuring reliability through skilled technicians, root cause analysis, quality parts, predictive maintenance, preventive maintenance programs, continuous improvement, testing and customer support, pushes the standards for the industry. As technology and maintenance practices continue to evolve, reliability in rotating machines will remain a key focus for industrial success and sustainable operations.